Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86-13678899682 directly.

Our wood slat acoustic panels combine natural veneer finishes such as Light Walnut with high-performance acoustic felt backing. Designed to enhance both sound absorption and interior aesthetics, these panels are widely used in offices, schools, and commercial spaces where stylish design meets noise reduction.

As decorative acoustic wall panels, these wood slat acoustic panels provide a linear, architectural look that reduces echo and reverberation. With technical veneer finishes like Light Walnut, they add warmth and sophistication to any space, making them a popular choice among architects and interior designers.

Acoustic Comfort Doesn’t Just Reduce Noise — lt Transforms How Your Team Works. From Enhanced Communication To Brand Professionalism, Our Solutions Are Trusted By Enterprises Seeking A Measurable Return On Design.

As an experienced acoustic panel manufacturer, we provide:

Made with formaldehyde-free, non-toxic materials, ensuring safety for indoor use.

The lightweight panel structure supports fast installation using clips, battens, or adhesive systems.

No specialized tools required—ideal for both new construction and renovation projects.

| Item | Details |

| Application Scenarios | Hotel, Study Room, Conference Room, Office, Home Theater, School, etc. |

| Engineering Solution Capability | Layout Design |

| Feature | Sound Insulation |

| Design Style | Modern |

| After-Sales Service | Online Technical Support |

| Warranty | 1 Year |

| Place of Origin | Shandong, China |

| Brand | Beien |

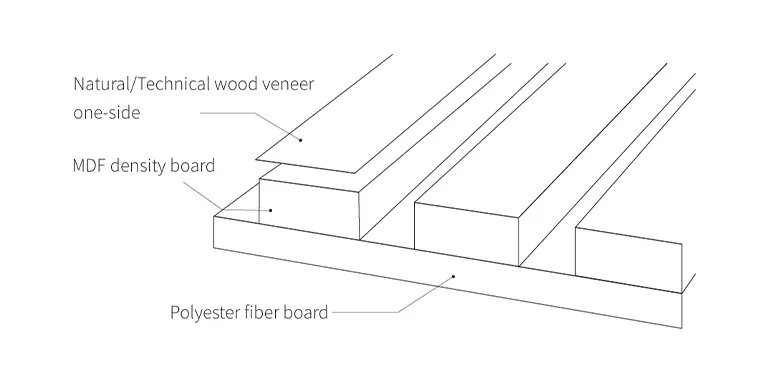

| Material | MDF + Polyester Fiber |

| Function | High Sound Absorption, Noise Reduction |

| Color | Customizable |

| Thickness | 21mm |

| Size | 600/2400/2700/3000 × 605 × 21mm |

| Usage | Indoor Room Soundproofing |

| Type | Soundproof Foam |

| Shape | Square |

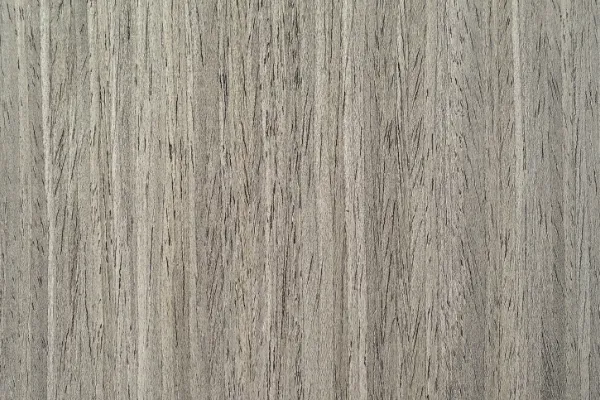

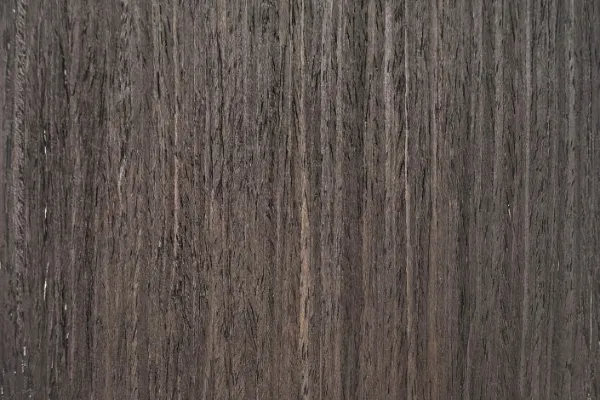

Uniform Texture and Color: Engineered for large-scale projects with consistent appearance and customizable patterns.

Enhanced Stability: Less prone to cracking, warping, or deformation compared to natural wood veneer.

High Durability: Wear-resistant surface, ideal for high-traffic commercial and public spaces.

Excellent Acoustic Performance: Effective sound absorption for noise reduction in various environments.

Customizable Options: Flexible in size, color, and surface finish to meet project needs.

Our standard MOQ is 100 panels per model, but we also support flexible low-MOQ options for new distributors, project samples, or trial orders. Please contact us to confirm based on your panel type and finish.

We accept T/T (Telegraphic Transfer) as our primary payment method:

30% deposit before production

70% balance before shipment

For long-term partners, other terms such as L/C or OA can be discussed.

Yes. All Beien products are certified by FSC, CE, SGS, and BSCI, and comply with E0 formaldehyde emission standards. We also provide testing reports for sound absorption, material safety, and fire resistance upon request.

Our standard lead time is 7 to 15 working days, depending on the order quantity and level of customization. For large-volume or special projects, we will provide a detailed delivery schedule before order confirmation.

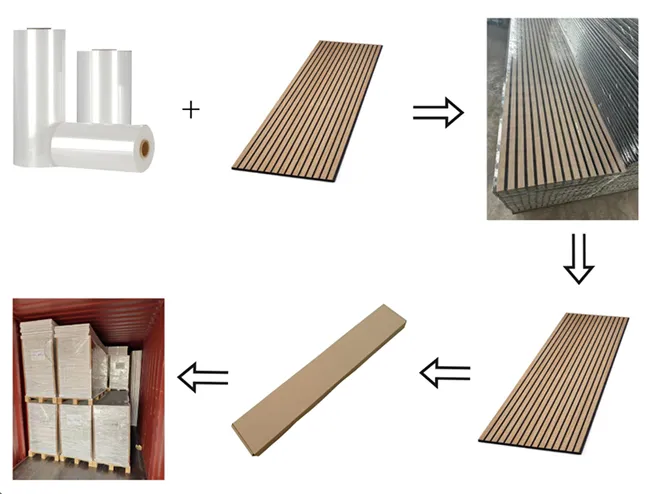

We provide FOB, CIF, and DDP terms with sea, air, or rail freight. Products are packed in cartons with wooden brackets (10 PET panels per carton) and wrapped with waterproof film. Bulk orders are palletized for safe loading and forklift handling.

Yes, we specialize in fully customizable acoustic solutions, including:

Size, thickness, and shape (e.g., slat, hexagon, 3D, curved)

Surface finish: natural veneer, PVC, technical wood, or PET

Color matching and design engraving

Custom packaging and branding

Send us your specifications, and our design team will support you with drawings, samples, and production plans.

Engineered panels use processed wood with adhesives and dyes that enhance stability and reduce risks of deformation and cracking.

Yes, their high sound absorption capability makes them perfect for creating comfortable and quiet indoor environments.

Yes, the engineered production process ensures color and texture consistency across large quantities, ideal for standardized projects.

Maintenance is simple—just clean the surface with a dry or slightly damp cloth. Avoid harsh chemicals to preserve the finish.

We package our wood slat acoustic panels securely to meet international transport standards. Each panel is wrapped in a protective film, stacked with foam or corner guards, and reinforced using carton boxes and wooden pallets. Moisture-proof and shock-resistant measures are implemented to prevent damage during transit.

Lead time: 7–12 working days depending on order volume.

Material: MDF + Polyester Fiber (with Technical Wood Veneer Surface)

Panel Size: 600 / 2400 / 2700 / 3000 × 605mm (custom sizes available)

Thickness: 21mm

NRC: Up to 0.85 (High Sound Absorption)

Finish Options: Technical wood grain, or customized finish

Colors: Multiple veneer tones or customized surface finishes

MOQ: 100 panels

Lead Time: 7–12 days

Usage: Interior wall and ceiling acoustic treatment in hotels, offices, theaters, studios, etc.