Als het antwoord op je vraag op zich laat wachten, voer dan je WhatsApp/Skype in samen met het bericht, zodat we meteen contact met je kunnen opnemen.

Je krijgt binnen 24 uur antwoord. In dringende gevallen kun je WhatsApp/WeChat toevoegen: +86-13678899682.

Unwanted noise in your office, studio, or commercial space is more than just an annoyance; it’s a barrier to focus, clarity, and productivity. This constant disruption agitates occupants and degrades the user experience. The solution lies in effective acoustic treatment that targets the specific sound issues of your environment.

Yes, in most cases, thicker acoustic panels are better for sound absorption and perceived soundproofing, especially when dealing with problematic low-frequency sounds like HVAC hum or bass tones.[1][2][3][4] A thicker panel has more mass and depth to trap and convert a wider range of sound waves into heat.[5] However, the ideal panel thickness is not a one-size-fits-all answer; it depends entirely on the frequencies you need to control and the primary use of the space.[2][6][7]

Before diving into thickness, it’s crucial to understand the primary role of acoustic panels. Their main purpose is to control the sound within a space by absorbing sound waves, which reduces echo and reverberation.[8][9][10] This is different from soundproofing, which aims to block sound from entering or leaving a room entirely. While the two are related, acoustic panels are designed for sound absorption and quality, not sound blocking.

When sound waves hit a hard surface like a glass window or concrete wall, they bounce back into the room, creating a chaotic and noisy environment.[11][12] An acoustic panel introduces a porous material that traps those sound waves.[11][13][14] As the sound energy travels through the panel’s fibers, friction converts it into a tiny amount of heat, effectively removing it from the room.[12][14][15] This process leads to:

As a professional manufacturer, we specialize in creating environments where sound is an asset, not a liability. Our solutions are engineered to provide superior sound absorption, ensuring every word is heard and every note is crisp.

What Is the Main Purpose of Acoustic Panels?

The thickness of an acoustic panel is directly linked to its performance, particularly concerning the frequency of the sound it can absorb.[3][5] Sound travels in waves, and different sounds have different wavelengths.

A panel’s thickness determines how effectively it can capture these waves. Thicker panels are necessary to absorb the longer wavelengths of low-frequency sounds.[3][4][19] A thin, 1 inch panel simply doesn’t have enough material to stop a powerful bass wave. In contrast, thinner panels (around 2 inch) can be highly effective at absorbing mid-to-high frequency sounds.[3][19] This is a critical consideration for architects and designers planning an acoustic treatment strategy.

The performance of an acoustic panel is often measured by its Noise Reduction Coefficient (NRC). The NRC is a rating from 0 to 1 that indicates how much sound a material absorbs.[5][6] A rating of 1.0 means 100% of the sound is absorbed. Generally, a thicker acoustic panel will have a higher NRC rating, especially across a broader range of frequencies.[5][6]

While thicker panels generally offer superior performance, especially for low-frequency challenges, they aren’t always the necessary or most cost-effective solution.[1][2] The key is to match the panel thickness to the specific acoustic needs of the environment. Over-engineering a solution with excessively thick panels can be an unnecessary expense.

For example, in a standard office where the primary goal is improving speech clarity and reducing conversational echo, a standard acoustic panel with a 2 inch thickness is often sufficient.[20] These panels absorb the high-frequency sounds of human speech very effectively. However, in a home theater or a large conference hall with a powerful audio system, thick acoustic panels (3 inches or more) or specialized bass traps are required to manage the powerful lower frequencies.[1][6]

The ideal panel thickness depends on a clear understanding of the room’s function. As a direct manufacturer, we provide customized solutions for our B2B clients, helping distributors, architects, and contractors select the precise thickness and density needed for optimal acoustic performance without overspending.

Matching panel thickness to the target frequency is the cornerstone of effective acoustic treatment. Here’s a general guide that we use when consulting with our clients:

| Frequentiebereik | Common Sound Sources | Recommended Panel Thickness | Waarom het werkt |

| High Frequencies (HF) | Human speech, office chatter, ringing phones | 1 inch to 2 inches | Short wavelengths are easily trapped and converted by thinner, porous materials. |

| Mid Frequencies (MF) | Music, television, most ambient noise | 2 inches to 3 inches | Requires more depth and mass than HF to effectively absorb the longer sound waves. |

| Low Frequencies (LF) | Bass music, HVAC systems, traffic, subwoofers | 3 inches or more (or specialized bass traps) | Long, powerful wavelengths need significant depth and density to be absorbed effectively.[3] |

For full-spectrum sound control in critical listening environments like recording studios, a combination of different panel thicknesses is often the best acoustic strategy.[15] This ensures a balanced acoustic environment where no single frequency range overpowers another.

What Is the Ideal Panel Thickness for Different Frequencies?

The acoustic requirements for a home cinema and a corporate office are worlds apart, demanding different strategies for acoustic wall panels and ceiling panels.

For most office environments, the primary goal is noise reduction to enhance focus and privacy.[16][17] The main culprits are speech, phones, and keyboard clicks—all mid-to-high frequency sounds.

A home theater is designed for an immersive audio experience, which involves managing a wide spectrum of sound, especially powerful low frequencies from subwoofers.[6]

While thickness is a primary factor, the density of the core material is equally important.[21] Density refers to the mass of the sound-absorbing material packed into the panel. A denser panel can provide better soundproofing and absorption even at a lesser thickness.

Imagine trying to stop a wave in water. A thin but very dense barrier might be more effective than a thick but very light one. The same principle applies to sound waves. This is where material science comes into play. Traditional acoustic foam panels can be thick but may lack the density needed for effective low-frequency absorption.

This is why we champion advanced materials like high-density PET (polyester) felt and composite wood panels. Our manufacturing process allows us to control the density precisely, ensuring our acoustic panels provide maximum performance. This gives our B2B clients—from building material importers to large project contractors—a competitive edge with a product that delivers superior results.

While thicker acoustic panels are generally better, strategic placement and material choice can allow for effective acoustic control with thinner panels. One advanced technique is to create an air gap behind the panel.

Mounting a 1 inch or 2 inch panel a few inches away from the wall can significantly boost its low-frequency absorption capabilities. The air gap acts as an additional sound trap, making the panel perform like a much thicker one without the added bulk or cost. This is an excellent strategy for designers and architects who need to balance acoustic performance with spatial and aesthetic constraints.

Furthermore, using a high-density material, like our PET felt, means even our relatively thinner acoustic options outperform bulkier, lower-density acoustic foam. This makes our polyester akoestische plaat an incredibly efficient and versatile solution for a wide range of applications.

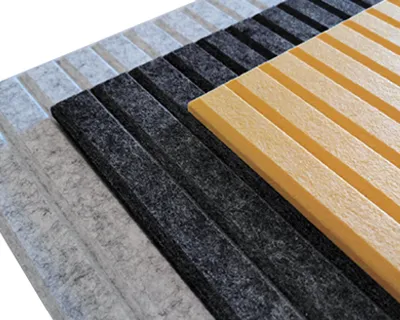

As a specialized manufacturer, we have deliberately focused on PET and wood as our primary materials, moving beyond traditional acoustic foam. This choice is based on superior performance, sustainability, and design flexibility—key considerations for our discerning global clients.

PET (Polyethylene Terephthalate) Acoustic Panels:

Akoestische panelen met houten latten:

For distributors and importers, offering our advanced PET and wood panels means providing a product that is acoustically superior, more sustainable, and aesthetically more desirable than standard acoustic foam panels.

What Is the Ideal Panel Thickness for Different Frequencies?

Choosing the right acoustic panel requires a thoughtful analysis of the space. As your manufacturing partner, we guide our clients through this process, but here are the key factors to consider:

For architects, interior designers, and brand owners seeking unique solutions, a direct partnership with a manufacturer like us is invaluable. Off-the-shelf products often cannot meet the specific aesthetic and performance demands of a high-end project.

As a specialist in custom acoustic panels, we offer OEM/ODM services that empower our clients to bring their vision to life. This includes:

By working directly with us, you gain access to our engineering expertise, quality control, and cost-effective production, ensuring your project receives a truly tailored and high-performance acoustic solution.

Does a 2-inch acoustic panel make a big difference compared to a 1-inch panel?

Yes, a 2 inch thick panel generally provides significantly better sound absorption than a 1 inch panel, particularly in the mid-frequency range.[6] While a 1 inch panel is great for taming high-frequency flutter echo, the added thickness of a 2 inch panel allows it to absorb more sound energy across a wider spectrum, making it a more versatile and effective choice for most common acoustic problems.[19][20]

Is thicker acoustic foam better for soundproofing?

While thicker acoustic foam will absorb more sound than thinner foam, it’s important to distinguish between absorption and “soundproofing.” Acoustic panels are designed to improve sound quality within a room.[21][26] For true soundproofing—blocking external noise—you need materials with high mass and density, often involving construction changes. However, thicker, high-density panels will provide better soundproofing results by reducing the amount of sound energy that can pass through them.[1]

What is the best thickness for acoustic panels in a recording studio?

A recording studio requires a balanced acoustic environment across all frequencies. The best approach is to use a combination of panel thicknesses. Use 2 inch to 3-inch panels at primary reflection points to control mid and high frequencies. Crucially, install very thick acoustic panels (4 to 6 inches or more), known as bass traps, in the corners to control the low-frequency resonance that can ruin a recording.[6]

How many acoustic panels do I need for a room?

The number of panels depends on the room’s size, its reflective surfaces, and the desired level of acoustic treatment. A common starting point is to cover 20-30% of the wall surface area. However, for critical listening spaces or rooms with severe echo, more coverage may be necessary. It’s often better to start with moderate coverage at key reflection points and add more if needed.

Can I make my own panels, and will they be as effective?

While you can make your own panels, achieving the performance of a professionally manufactured acoustic panel can be difficult. We use high-density, fire-rated materials and precision engineering to maximize sound absorption and ensure safety. Our PET and wood panels also offer a level of aesthetic finish and durability that is hard to replicate in a DIY project.

Are wood acoustic panels better than PET felt panels?

Neither is inherently “better”; they serve different needs. Full PET felt panels often provide slightly higher overall sound absorption because their entire surface is porous.[27] Wood acoustic panels offer a unique combination of absorption (from the PET felt backing) and diffusion (from the wood slats), creating a very natural sound. The choice often comes down to balancing acoustic goals with aesthetic preferences, where wood provides a premium, decorative finish.[18][27]

Ready to create an acoustically optimized environment that enhances productivity and elevates the user experience? Contact us today to discuss your project. As a leading manufacturer of high-quality PET and wood acoustic panels, we provide the customized solutions and expert guidance that distributors, architects, and contractors need to succeed. Let’s build a better-sounding world together.