Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86-13678899682 directly.

Noise makes rooms feel busy and tired. Left alone, echoes pile up and speech blurs. The fix is simple: choose the right acoustic panel—matched to your space and goals—for clear, calm sound.

When you buy acoustic panels, check five things: your acoustic needs, target frequencies, NRC (sound absorption) rating, panel thickness and material (PET felt or wood panels), and installation layout for walls or ceiling. Panels with high NRC reduce reflections and absorb sound waves so speech and music feel clean. Plan placement, quantity, and finish to fit your room and design.

As a professional manufacturer in China making high-quality PET and wood acoustic panels for global B2B clients, we’ve helped architects, distributors, and contractors map a clear acoustic treatment path for offices, schools, home theater rooms, and large public halls. Below is a practical, vendor-neutral guide to help you choose the right acoustic solution for your space—step by step.

Quick note: Throughout the guide, we’ll reference detailed product pages (internal resources) so you can dive deeper into materials, finishes, and test data.

An acoustic panel is a sound-absorbing surface—made of PET felt, mineral fiber, or foam panels—that reduces echoes by turning sound waves into tiny amounts of heat. In practice, the panels absorb mid- to high-frequency energy that would otherwise bounce off hard walls and ceiling.

When panels are designed to absorb sound, they carry an NRC (Noise Reduction Coefficient) score. NRC 0.70, for example, means the acoustic panel absorbs 70% of incident sound energy in the test band. Panels with high NRC ratings improve sound quality for speech and music and enhance the acoustic comfort of a room.

What is an acoustic panel, and how does it work?

Explore real-world PET felt options: see our polyester fiber acoustic panels for walls and ceilings, including thickness, NRC, and colors (great starter resource for the acoustic treatment plan).

NRC & Frequency: The level of sound absorption depends on material and thickness. Thicker panels generally provide better sound absorption, and some constructions are effective at absorbing lower frequencies.

Room Goals: Define acoustic needs first. Is your aim speech clarity, lower reverb, or a warmer music mix? Your acoustic goals shape the panel choice and placement.

Project Scope: Surface area, number of panels needed, timeline, and finishes are factors to consider when buying.

NRC Cheat-Sheet (typical ranges)

| Panel Type | Common Thickness | Typical NRC | Best Use Case |

| PET Felt acoustic panel | 9–12 mm | 0.75–0.90 | Workspaces, classrooms, restaurants |

| Acoustic foam panels | 25–50 mm | 0.60–0.85 | Practice rooms, studios (mids/highs) |

| Perforated wood acoustic panels | 12–18 mm | 0.60–0.85 | Auditoriums, offices (tunable + decorative) |

| Acoustic baffles (ceiling) | 24–50 mm | 0.70–0.95 | High-ceiling halls; budget-friendly coverage |

Deep-dive on PET felt options and NRC benchmarks in our product primer:

→ Internal link: sound absorption panels (PET felt)

PET Felt Acoustic Panel

Made from recycled polyester, PET felt acoustic panels are clean, stable, and easy to fabricate. Panels are lightweight, color-rich, and panels come in various sizes. They’re effective acoustic solutions for offices and schools.

Acoustic Foam Panels

Foam comes in flat, wedge, and pyramid foam panels. Foam is effective at absorbing mids/highs; however, acoustic foam soundproofing is a common misconception—foam is absorption, not isolation.

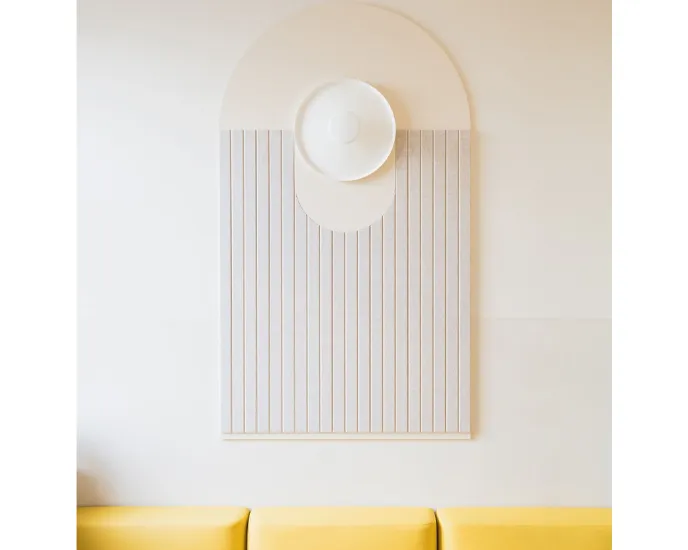

Perforated Wood Panels

Perforated wood acoustic panels are engineered wood panels with drilled or slotted faces backed by acoustic fleece and air cavity. They balance warm looks with strong sound absorption.

Browse options that combine performance and design:acoustic wooden slat wall panels

Walls First: Early reflections near listeners cause most clarity problems. Start with side-wall and back-wall treatment using acoustic panel arrays that absorb sound waves and reduce flutter echo.

Ceilings for Large Rooms: In cafés, classrooms, or open offices, acoustic ceiling panels and clouds or hanging panels add coverage where walls are mostly glass. Ceiling arrays can provide better sound absorption per square meter when wall area is limited.

Want a quick tour of ceiling-friendly PET options? polyester acoustic board (ceiling/wall use)

Simple Rule of Thumb: Start with 15–30% wall/ceiling coverage with acoustic panel surfaces; adjust after listening tests. The number of panels depends on room size, target RT60 (reverberation time), and usage.

Placement: First arrange the panels at early-reflection points, then fill remaining echo paths. For speech rooms, prioritize the front half of the room. For music, balance front and rear.

Need help sizing? Use the room’s volume and target RT to calculate foam panels or PET felt coverage for your specific acoustic goals. For studio-grade advice, see our dedicated pages:

acoustic panels for home studio

Foam: Good for mids/highs. Look for best acoustic foam formulas validated by third-party testing. Foam panels are commonly used in practice spaces and small studios and are designed to absorb sound—not block it.

PET Felt: Cleaner aesthetics, strong NRC, richer color library, and easy CNC cutting. PET panels are lightweight and panels feature consistent density.

Wood Slats/Perforated: When you want diffusion + absorption, slat or drilled wood acoustic wall panels create rhythm on the wall and reflect sound in a controlled way while still absorbing energy via backing.

For a material-by-material tour and panels with high nrc ratings, scan these:

custom acoustic panels (PET/wood)

acoustic panels for home theater

foam vs. PET felt vs. wood slats

Home Studio: You need acoustic control for clean recordings. Treat the mic’s reflection zone first, then corners for low-frequency sound control (bass traps), and finally rear-wall diffusion with acoustic diffuser panels. The acoustic treatment cannot be overstated: clear monitoring equals better mixes.

Home Theater: In small rooms, low-frequency sound booms easily. Combine thick PET felt, tuned acoustic diffuser elements, and layout symmetry. Panels might focus on side walls first; add acoustic ceiling panels if floor and furniture are reflective.

For practical layouts with color options and NRC ranges, start here:acoustic panels for home theater

These factors to consider include:

Compare PET and wood options suitable for offices and learning spaces:office acoustic wall panels

Hardware Options: Z-clips, adhesives, magnets (for steel), and cable kits for clouds. For hanging panels from the ceiling, follow mechanical codes and check plenum restrictions.

Installing Acoustic (Step-by-Step):

Map early reflection points.

Use a level to mark lines; installing acoustic panels with proper spacing improves coverage.

Install the panels with rated anchors.

Seal edges where required; verify fire and sprinkler clearances.

Quick reference for wall/ceiling PET felt systems:PET felt acoustic panels (product family)

Customization: Colors, thinner panels or thicker cores, CNC cutouts, logos, printed branding, and integrated lighting. That’s where custom acoustic panels shine.

Lead Time: Stock colors ship fast; custom colors add time. For large venues, plan procurement alongside other trades.

Budgeting: Balance coverage and NRC. Panels that fit your schedule may prioritize quick-ship SKUs first, then add feature walls later. For large volumes, OEM/ODM helps align specs and packaging.

See the range of acoustic panel options for quick-ship and bespoke projects:sound absorbing panels (PET felt family)

Step 1 — Define Use

Meeting room (speech), home theater (cinema), classroom (speech + comfort), or café (noise control).

Step 2 — Pick Type

PET felt for color and coverage; acoustic foam panels for practice rooms; perforated wood panels where design and durability matter.

Step 3 — Select Thickness

9–12 mm PET for speech; add air gap for stronger sound absorption; thicker cores for music rooms.

Step 4 — Layout

Side walls first. Add ceiling clouds if glass or concrete dominate. Use acoustic diffusers on back walls in music spaces.

Step 5 — Verify & Iterate

Listen, measure, adjust. Your acoustic treatment journey evolves with the room.

How to Choose the Right Acoustic Panels

“Do acoustic panels don’t change low bass?”

Not directly. Most thin panels excel above ~250–500 Hz. For bass, use thick absorbers, membrane traps, or furniture/boundary changes.

Performance Snapshot (Illustrative)

| Goal | Material | Result (RT60 Reduction) | Notes |

| Speech clarity | 12 mm PET acoustic panel | -0.4 s | Side-wall coverage + back wall |

| Open office comfort | PET clouds (ceiling) | -0.3 s | Clouds above desks |

| Small home theater | PET + slat wood panels | -0.5 s | Add corner bass control |

| Music practice | acoustic foam panels | -0.3 s | Mids/highs control |

See living examples and decorative finishes:acoustic wooden slat wall panels

Understanding acoustic foam: Foam controls reflections inside a room; it doesn’t stop noise passing through walls. That’s isolation, which needs mass, damping, and decoupling. Understanding acoustic foam helps you set the right expectations, especially if you’re setting up a home recording space.

Acoustic foam for your space does a fine job with flutter, comb filtering, and sibilance—but plan structural upgrades (drywall layers, seals) if true isolation is required. For mixed spaces, combine foam with PET felt and slatted wood acoustic panels to balance tone.

Challenge: Loud, splashy room; speech hard to follow; staff fatigue.

Solution: PET felt acoustic panel arrays on side walls + acoustic ceiling panels over main seating.

Outcome: RT60 trimmed from 1.3 s to ~0.7 s; complaints dropped; table-turns improved.

“We started small and added more arrays as needed—simple changes that improve sound without heavy construction.”

How do I choose the ideal acoustic panel for my space?

List your acoustic requirements (speech vs music), pick material (PET, foam, or wood), target an NRC ≥0.75 for speech spaces, and plan coverage on walls and ceiling. If in doubt, start with PET felt, then add wood slats for style.

Do I need diffusers or just absorbers?

For speech-first rooms, absorption wins. For music, add acoustic diffusers or acoustic diffuser panels on the rear wall to keep life in the room while controlling echoes.

Can I DIY acoustic panels?

Yes—diy acoustic panels using fabric-wrapped mineral wool and frames work well. Ensure safe materials and correct mounting for walls and ceiling.

What about maintenance and cleaning?

PET felt wipes clean and resists pilling. Perforated wood panels handle bumps better. In busy areas, slats and wood faces are tougher.

Is foam enough for bass?

Often no. Use thick absorbers, corner traps, or tuned solutions. Foam is effective at absorbing mids/highs; combine with other tools for bass.

Can I hang panels from the ceiling?

Yes—use rated cables and anchors. Always check sprinkler and code clearance for acoustic ceiling panels and clouds.