Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86-13678899682 directly.

Echoes, noise complaints, and speech that’s hard to hear waste time and energy. Left unsolved, they frustrate users and age your space fast. Durable acoustic panel systems fix the problem and keep working for years with simple care.

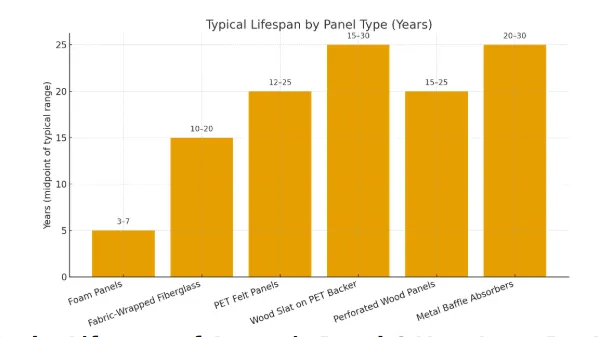

The lifespan of acoustic panels depends on material and care: PET and wood veneer wall panel systems typically last 12–25 years; fabric-wrapped panels 7–15 years; perforated wood 15–30 years; foam panels about 3–7 years. Proper installation, regular cleaning, controlled humidity, and limited UV/heat help panels last longer.

The lifespan of an acoustic panel is driven by material quality, how the panels are installed, and day-to-day use. Panels designed to absorb sound (not block it) turn sound waves into tiny amounts of heat. Over time, dust and dirt, sunlight, and handling can change the appearance and acoustic behavior of the surface. With proper maintenance, most high-quality acoustic panels deliver stable acoustic performance for many years.

Environmental factors matter. Humidity, temperature swings, direct sunlight, and abrasion in high-traffic areas can shorten longevity. When environmental conditions are controlled and maintenance practices are simple and routine, panels can last well beyond their warranty window.

As a professional manufacturer, we design PET and wood acoustic wall panels for tough commercial settings. In our experience using panels with the right substrate and finish is the easiest way to extend the life of acoustic panels.

The lifespan of acoustic panels varies by material and finish. Different types of acoustic builds behave differently in the field.

Table: Typical Service Life & Care

(See the interactive table and chart below for a quick comparison.)

Typical Service Life & Care

When select panels for harsh sites, choose moisture-resistant panels and thicker panels; the latter often tolerate dings and keep their shape.

A good acoustic panel solves acoustic issues fast and stays neat. Look for:

Quality wall panels offer stable absorption, corner integrity, and color fastness. Panels manufactured with consistent density and skins hold their edges; panels made with low-density scrap crumble early.

Tip. Ensure that the panels and adhesives are compatible; incompatible glues can harden fibers and reduce acoustic performance.

Yes, but it’s simple. Regular cleaning and maintenance keep the appearance and acoustic performance stable. Vacuum with a brush attachment, spot clean with a mild agent, and keep panels away from heaters. Most panels require nothing more.

This is the core of durability and maintenance: light, frequent care beats heavy scrubbing. For fabric surfaces, use a soft cloth and dab—don’t rub. For wood, wipe along the grain. PET tolerates lint rollers well.

No—panels absorb sound waves inside the room; they don’t “seal” walls like mass-loaded barriers. Panels are an effective acoustic treatment for echoes, flutter, and reverb, improving the acoustic environment and helping improve sound quality. For isolation (soundproof goals), pair panels with added wall mass, sealed doors, and decoupling.

That said, panels are effective at clarity: better speech, calmer rooms, fewer hotspots.

For panels in rooms like corridors, schools, retail, and arenas—true high-traffic areas—choose PET or engineered wood panels with durable skins. These panels are extremely tolerant of bumps and trolleys. Avoid light-density foams near kids’ reach or sun-splashed glass where UV is strong.

Think about specific acoustic goals too: speech clarity vs. music warmth. Choosing the right acoustic build (PET felt vs. perforated wood) yields the desired acoustic result and longer life.

acoustic panels for high-traffic areas

Proper installation prevents sagging, edge chips, and failures. Use rated adhesives and anchors; align seams; keep tolerance on trims. Floating clips let panels to ensure replaceability and airflow.

When panels are installed with room for expansion/contraction, you cut edge cracks. Well-set reveals also protect corners in high-traffic corridors.

Here’s how to extend the life:

Follow this and panels will last. In controlled sites, many PET and perforated wall panel systems last decades.

Consider replacement if you’ve considered purchasing new acoustic panels due to:

These indicators that panels are at end-of-life often show up with old panels in gyms or sun-heavy lobbies.

A shopping mall concourse (very high-traffic) used PET acoustic wall panels at 9 mm thickness with 24 mm air-gap. After 8 years, only 2% of panels needed spot service. Why did these panels last? Daily dry-mop dusting, quarterly vacuuming, and balanced HVAC.

PET and engineered wood panels offer toughness; panels come in modular sizes, so single-panel replacement is fast.

long-lasting panels in a commercial project

Key durability signals:

Panels designed with higher density hold staples and trims better. Panels are designed to absorb sound efficiently when the core stays porous; over-painting can block pores and reduce efficacy.

From a lab view, look for proven acoustic properties (NRC/SAA) and documentation; NRC is measured per ASTM C423 and can guide select panels for your target frequency range.

Buy panels from reputable factories with consistent fibers and coatings. Ask for project lists, stability tests, and sample cleaning. Confirm whether panels manufactured under your brand allow private labeling, custom sizes, and panels for signs (e.g., custom-printed PET that doubles as wayfinding).

Check warranty terms around colorfastness, cleaning, and environmental conditions. This helps ensure that the panels you get are high-quality and long-lasting.

We’re Beien Construction Co., Ltd, a professional manufacturer in China specializing in high-quality PET and wood acoustic panel systems for global B2B clients. We offer OEM/ODM with custom cuts, veneers, perforation patterns, and printing (great for panels for signs and branding). Our PET felt uses recycled fibers and stable pigments. Our veneers meet E0-class emissions; we support CE and FSC documentation.

For distributors, architects, and contractors, we provide:

If you’re planning different acoustic zones—libraries, lobbies, classrooms—we’ll help select panels to improve sound quality and keep maintenance light.

How long do PET acoustic panels last?

With proper maintenance, PET acoustic panel systems typically run 12–25 years. Keep them out of intense direct sunlight and vacuum with a brush attachment to keep fibers neat.

Do panels make a room soundproof?

No. Panels are acoustic absorbers, not barriers. They reduce reverberation and echo for clarity. For isolation (soundproof goals), add mass, seal gaps, and consider resilient channels.

What’s the best panel for high-traffic areas?

PET felt and engineered wood panels. They resist knocks and clean well. Fabric panels look premium but need gentler care.

When should I replace panels?

Replace if faces are stained, edges crumble, or your measured reverb rises. That’s often when indicators that panels are past life show up.

Can I print graphics on panels?

Yes. We supply custom-printed PET that doubles as wayfinding—great panels for signs in malls and schools—without harming absorption.

What affects lifespan most?

Material quality, UV, humidity, and cleaning. Manage those, and panels can vary significantly depending care, but many panels are ideal for long-term use.

Ready to spec panels that last? Tell us your room size, target NRC, finish, and timeline—we’ll send cut-sheets, samples, and a fast quotation.