Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86-13678899682 directly.

Noisy streets, echoey rooms, and thin walls drain focus. The noise level creeps up; unwanted noise leaks through walls and ceilings and the ceiling above. The fix is simple: combine sound isolation, insulation, and smart build details to block, absorb, and dampen vibrations—quiet you can feel.

Sound isolation stops noise from passing through structures; soundproof insulation improves blocking by adding mass and absorption. For a ceiling or wall, use multiple layers of drywall, a damping compound (like green glue), dense wool insulation, and decouple the surfaces. This combo reduces sound transmission, raises stc, and delivers real db cuts.

Sound isolation means stopping sound transfer from one space to another, mainly by adding mass, decouple-ing surfaces, and controlling vibration. Soundproof work targets the full path—airborne leaks, conduction through framing, and panel resonance. In simple terms: block, separate, and calm the shake.

Many people reach first for foam. It helps inside a room because it improves absorption and makes a space less reverberant, but isolation is different. In small amounts, foam will significantly improve echoes, not blocking. To truly reduce sound transmission, you need mass, sealed edges, and smarter construction—not acoustic foam alone.

For tuned wall treatments that control reflections while you build isolation into the assembly, see our polyester fiber acoustic panels.

What is sound isolation

A wall or ceiling is a system: outer sheathing, drywall, studs, cavity fill, and finish. Noise moves as pressure (airborne) and as structure-borne conduction. When sound waves hit a surface, part reflects, part turns to heat (via sound absorption inside the cell structure of materials), and part passes through.

To block better, assemblies rely on adding mass (thicker boards), strategic decouple (channels or staggered stud), and viscoelastic sound damping layers. Inside the cavity, dense wool insulation or fiberglass helps attenuate mid-band frequency range energy. Together these steps lift stc performance and yield tangible db and db reduction benefits in daily use.

Explore dense PET felt sound absorbing panels for the finish layer to calm room echoes after isolation is in place: sound absorbing panels.

Every panel has a resonance point where it loves to vibrate. Large, light boards ring; double layers shift that resonance downward while damping keeps peaks tame. If a wall or ceiling shares studs, vibration passes easily—this is why people experience soundproofing problems even after adding layers.

Solutions that reduce resonance combine damping compound between boards (e.g., green glue), decouple with resilient channels, and keep edges sealed. Think of energy as sound energy: if it can’t couple cleanly, it dies out. Our wood veneer wall panels can finish an isolated assembly with warmth while preserving control: wood veneer wall panels.

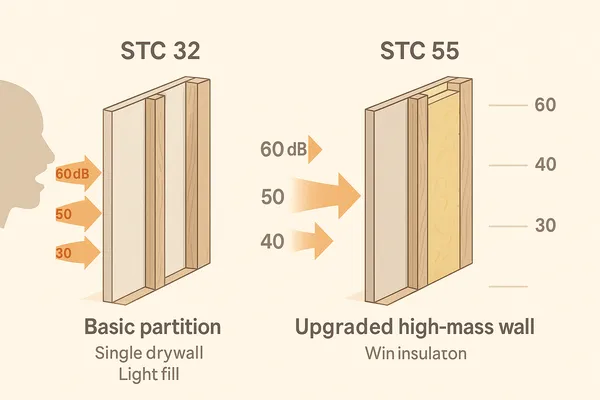

stc (Sound Transmission Class) predicts speech blocking between typical rooms. Remember, decibel scales are logarithmic: +10 db sounds roughly twice as loud to many listeners. A standard interior partition (single drywall each side, light fill) might score in the low 30s; upgraded builds push into the 50s+.

What is STC and how many dB do you need

Table: Typical Assemblies and Expected Sound Reduction

| Assembly (simplified) | Approx. STC | Notes on sound reduction |

| Single 1× drywall, no fill | ~33 | Light mass, weak isolation |

| Double drywall + wool insulation | ~45–50 | Better blocking and absorption |

| Double drywall + green glue + dense fill | ~52–58 | Adds damping compound |

| Decoupled (channel) + mass + dense fill | ~55–63+ | Strong isolation |

When planning offices, studios, or classrooms, aim for assemblies that meet your target levels of noise. For spaces like an auditorium, isolation needs rise along with internal acoustics goals.

For packaged, project-ready finish options after isolation, see wood slat wall panels.

Decouple means breaking the rigid path so vibrations don’t pass straight through. Methods include resilient channels, clips, or staggered stud walls. With channels, where the drywall is attached matters: screws must hit the channel, not the stud, to keep the air space floating.

Add viscoelastic layers between multiple layers of board to dampen sound further. If budget allows, a “room within a room” (full framing separation) is the gold standard. After structure, finishing with tuned PET or wood treatments helps improve sound inside the space: try PVC noise reduction panels for durable, wipe-clean finishes.

How to decouple a wall or ceiling for better noise isolation?

mlv (mass loaded vinyl) is a flexible sound barrier sheet. It adds mass where board layers are constrained by thickness or weight. Mineral or fiberglass batts and dense wool insulation excel as absorption material inside cavities. Rigid melamine sheets help with finish absorption.

What about foams? acoustic foam (often open-cell) helps in-room echo control, not blocking; open cell types breathe, open-cell designs trade mass for absorption. Another acoustic foam variant can help higher bands, but for low frequency problems, mass and decouple dominate. Use foams as treatments, not primary blockers.

See PET felt finishes that pair well with isolated walls: PET felt panels. For slatted diffusion plus absorption, explore the acoustic slat panel.

Downward thumps—impact noise—travel through structure. To calm footfall, float the subfloor or topping on pads (cork, rubber, neoprene), add underlay, or isolate the joist interface. Even a thin, properly chosen underlayment can dampen the energy that tries to jump across the structure.

Where you can’t rebuild, add ceiling-side isolation below: clips + channel + mass. Tie-ins at beams and the second joist layer are critical. Finishes like slat wood can soften the reverberant character of large rooms; try wooden soundproof panels when you also want a tactile timber look.

Panels and foams serve different roles. Use acoustic panels (fabric-wrapped PET, wood slats with felt backing) to tune reflections and speech clarity; they’re sound-absorbing finishes that make rooms feel calmer. Foams can be helpful for early reflections but aren’t your main blocker.

For finish choices that suit modern interiors and building materials schedules, browse wood slat wall panels again for diffusion-plus-absorption, or pick materials used in offices and studios such as polyester acoustic board alternatives when you need lighter, easy-to-install surfaces.

Isolation leaks at edges, outlets, and seams. Use acoustic caulk around board perimeters and a putty pad at boxes. Aim for airtight continuity: if air leaks, airborne noise leaks. Choose smart building materials, mind thickness, and confirm every seam is sealed.

Where trims meet the ceiling or floor, keep breaks continuous. Be mindful of wood framing bridges. A tiny gap undone can undo a lot of noise isolation. Finish with a washable, decorative PET face where needed—see noise reduction panels.

Quote: “Design for the path the sound wants to take, and it won’t arrive.”

Example target: For a conference room beside an adjacent room, aim for a wall assembly delivering stc 55+. That typically means double board, green glue between, dense fill, and channel decouple. Expect clear speech privacy and measurable noise reduction in day-to-day use.

Simple Before/After Table

| Metric | Before | After |

| Average speech spill (A-weighted) | 48 db | 34 db |

| Subjective privacy | Poor | Good |

| Reported distraction | High | Low |

Finish layers that match design briefs: wood slat wall panels or PET-based sound absorbing panels.

A ceiling often needs clips + channel + double board. Keep services in the plenum, preserve air space, and avoid rigid backers touching the isolated shell. When fixtures must mount, use isolation grommets.

If you’re unsure, a reputable soundproofing company or our engineering team can propose soundproofing solutions using PET and wood finishes that match your brand palette—without sacrificing performance. For design-led options, explore wood slat wall panels one more time for continuity across ceilings.

Isolation adds like resistors in series, and conduction loves shortcuts. One missed seam or rigid backer can bypass the best layers. Remember that sound transmission paths add up, and STC ignores low frequency rumbles; doors, glazing, and ducts need equal care.

When you insulate cavities, pick density that fits the assembly. Visco layers help across a wide frequency range, and sound barrier sheets can help when mass is limited. Pick finishes that are used for sound control and visual warmth—see custom PET and wood options on our site for coordinated packages.

Is “more foam” enough to soundproof a room?

No. Foam treats internal echo but not isolation. Use mass, decouple, and sealed layers; then add treatments to polish in-room acoustic quality.

Will panels fix traffic noise from outside?

Treat the shell first: windows, doors, and wall mass. Then add tuned finishes like PET felt to address traffic noise reflections.

What if I can’t rebuild the wall?

Add a new drywall layer on channels with a damping compound, seal with caulk, and finish with decorative PET. It’s a fast retrofit.

Do I need special expertise to choose finishes?

We’re a manufacturer of PET and wood solutions for B2B teams. We help architects and contractors match finish, performance, and budget—globally.

How do I handle tricky ceilings with services?

Use clips, channels, and maintain air space. Route services through independent hangers; avoid rigid ties into the isolated shell.

As a China-based manufacturer of PET and wood acoustic finishes, we support distributors, designers, and contractors with OEM/ODM deliverables. We coordinate isolation-first builds and provide finish packages that meet specs and timelines. From small offices to large public builds, we help teams soundproof without losing design intent.

Block: Use mass, multiple layers, and sealed edges.

Break: Decouple with channels or clips; avoid rigid bridges.

Calm: Add absorption inside cavities; finish with PET or wood slats.

Seal: Caulk every seam; pad boxes with putty.

Verify: Review fixtures at the ceiling and floor so nothing ties through.

Finish: Choose finishes that improve sound inside the space and match the spec.

A tech client had “paper walls.” We designed a clip-and-channel shell, added dense fill, two boards with green glue, then finished with PET slats. Result: clearer speech privacy, better focus, and happier teams. We measured db cuts across speech bands matching the plan, and the acoustic finish lifted visual quality too.

Note: If you need coordinated finish packages for offices, hospitality, education, or public works, our team supports specs, samples, and fast global dispatch—quietly and reliably.