Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86-13678899682 directly.

Hard rooms build echo. Meetings blur, learners tire, and music turns harsh. A polyester acoustic panel adds clean sound absorption, cooling the room’s tone without heavy construction.

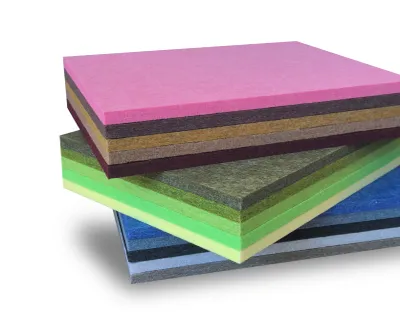

A polyester acoustic panel is a porous felt panel with a polyester core that turns sound energy into heat. Mounted on walls or ceilings, it cuts reverberation, raises speech clarity, and is easy to install. It’s durable, eco-friendly, often recyclable, and available in many finishes for interior design.

A polyester acoustic panel uses a dense web of fibre strands that is thermal bonded into a stiff felt. The web is porous. Tiny air channels slow the wave so friction can convert acoustic motion into heat. That is absorption in simple terms. Because the network is a tuned absorbing core, mids and high frequencies are handled with confidence.

In practice, panels placed on walls or ceilings intercept early reflections. That trims reverberation and improves the sound quality for talk and music. A first pass over a meeting table or along a sidewall will absorb sound waves before they bounce between flat surfaces. When the brief calls for a clean felt face, PET felt acoustic panels are a common pick; see real-world thickness and mounting notes under the patterns used for PET felt acoustic panels.

To tune the band, vary thickness and the air gap. A 12 mm panel near a talker focuses on intelligibility. Add a 25–50 mm gap and the low-mid lift is clear. For ceiling-first strategies, look at how projects deploy polyester fiber acoustic panels when planning ceiling baffles and clouds: polyester fiber acoustic panels.

What is a polyester acoustic panel

Different absorbing materials behave differently. Fiberglass and rock wool boards excel when maximum sound absorption and rigidity are needed behind fabric systems. Acoustic foam panels are light and easy but can underperform at lower bands unless thick. PET felt strikes a middle ground: clean handling, cut-to-shape freedom, and a finished face.

For design-forward spaces, PET helps you meet visual appeal without extra fabric. It also arrives as sheets, slats, or cut forms—fast to field-trim. If you need a board-like sheet with crisp edges, check specs similar to a polyester acoustic board used as a base layer beneath screens or slats; see layouts that mirror this approach in polyester acoustic board references.

Indicative comparison (guide values only):

| Material | Handling | Typical NRC (25–50 mm system) | Notes |

| PET felt (polyester panels) | Clean cutting, low dust | 0.75–0.95 | Finished face; good for arrays and clouds |

| Fiberglass | PPE recommended | 0.80–1.00 | Strong per-thickness absorption; fabric wrap |

| Rock wool | PPE recommended | 0.85–1.00 | Rigid; great in utility areas |

| Acoustic foam panels | Easy to stick | 0.40–0.80 | Watch thickness and fire data |

When you want patterned faces and airflow, the decorative PET range is helpful—see how teams use slotted and perforated faces in project galleries similar to PET polyester acoustic panels.

Rooms color sound through reflections and time decay. Acoustics basics say: target early reflections first; then balance overall decay. Absorption solutions cut the tail and clear speech. Diffusion scatters energy so the space stays lively without harsh flutter.

The material for sound absorption must be open enough to slow the wave yet strong enough to hold shape. PET’s bond of tangled strands fits this: it is sound-absorbing and stable. One must not confuse isolation with treatment: blocking transfer needs mass; treatment reduces in-room splash. A simple way to plan sound acoustic performance is to mix coverage areas and gaps for even absorption efficiency across the band.

Designers often begin with first-reflection stripes, then add clouds or baffles. That keeps the room “present” while cutting noise and reverberation. For reference photos of slats, baffles, and flat sheets arranged in working spaces, browse examples comparable to acoustic wall panels in studio-type layouts.

Reflections usually come from planes facing the listener. That is why many projects start with ceiling fields over seating or desks. Clouds reduce glare while preserving circulation. On the lateral wall panels, target parallel paths to stop ping-pong bounce.

In small conference rooms, a balanced approach is best: a ceiling cloud above the table, sidewall bands at ear height, and a back-wall array. This controls echo and focuses talk without deadening the room. When the room doubles as a camera space, keep clean backgrounds and hide lights within cloud gaps. See how “cloud + stripe” patterns echo what’s used in practice under hanging dividers and ceiling elements.

Large rooms need scale. In an auditorium, treat the rear wall high and add baffles over aisles. Angle or curve surfaces where possible so remaining reflections wash evenly across seats. For open plan offices, review neutral PET felt schemes similar to acoustic panels for office.

Where should we mount acoustic panel systems

Start with purpose. Talk-first rooms need clarity; music rooms need richness. A simple estimate: cover 20–35% of the effective surface area in talk spaces, then listen and add more where hot spots remain. The goal is to reduce noise and bring the decay to a comfortable window.

Tip: a little fibre felt placed exactly at first reflections can beat a bigger, random patch elsewhere. Short paths carry the most influence.

A school classroom or small meeting room often lands near 10–15 m² of PET felt at 12–18 mm, split between ceiling and walls. For media or home theaters, go heavier on sidewalls and the front reflection zone. For image-rich examples that resemble these patterns, see common choices in acoustic panels for home theater.

PET felt is color-through. You can specify a variety of colors, edges, and cuts to match branding or wayfinding. Circles break up rigid grids. Slats add rhythm. Flat sheets give a calm backdrop. All keep the broad-band behavior if thickness and spacing are right.

Because the panels cut cleanly, teams mix shapes and sizes—tiles, ribbons, baffles—to meet interior design intent. Flat arrays double as art; slotted faces help airflow over return paths. When you need a decorative face, explore patterned panels similar to the perforated families shown under decorative acoustic panels and slotted designs, e.g., examples like engraved or slotted PET concepts.

These systems remain acoustically effective if you keep airflow behind the face and maintain the gap. The result is performance with style, useful in various applications from galleries to classrooms to social hubs.

special design of pet panels

Public spaces require fire protection that is proven and documented. Many PET systems achieve class a fire performance in the common test tunnel and are listed as class a fire rated when configured per the test report. Always verify certificates for the exact build and thickness.

Beyond ratings, coordinate sprinklers, detectors, and egress signs. Walls and ceilings need clearances and secure anchors. Choose adhesives and fasteners that match the substrate and code. For ceiling fields, use mechanical hardware rated for overhead duty and note service access. You’ll find many projects deploy PET as a front layer only, keeping plenum airflow intact, as seen in large-area examples akin to PET polyester acoustic panels.

Facts at a glance

Felt made with recycled polyester supports circular goals. PET systems are typically eco-friendly and often recyclable, making them a sustainable product choice when documentation is required. Installers like the clean handling and low dust.

Surface durability matters in busy corridors and commercial buildings. PET resists dents better than many soft wraps. It also keeps a finished face, so fewer layers are needed. If you need a smooth board look that is still soft to the ear, browse PET options that resemble polyester fiber acoustic panels used as boards.

“Healthy project” specs often include VOC and emissions requirements. PET’s inert felt helps here. It is an environmentally friendly acoustic product that plays well with low-odor adhesives and clean-site rules.

In recording studios, PET arrays kill flutter while leaving room for diffusion on the back wall. In home theaters, sidewall stripes and a front cloud keep dialogue crisp and panning smooth. Houses of worship require sightline-safe arrays high on the rear wall plus discreet ceiling banners.

Mixed-use sites—museums, libraries, courts—demand subtlety. PET can dress as art or trim while doing acoustic work. For residential and commercial conversions, felt sheets hide rough masonry yet smooth the acoustic. If you need reference images for media rooms and offices, check galleries similar to acoustic panels for home studio.

Sometimes you need noise reduction fast in a retrofit. PET tiles and ribbons install quickly and scale to large walls. They help tame noise and echo without heavy work. In busy halls or an auditorium, baffles over aisles even out decay across seats.

Most PET arrays are easy to install with concealed clips or rated adhesive. The panels are made to trim cleanly on-site, so openings for screens, signs, or fixtures are simple. Panels are also robust enough for classrooms and transit corridors.

The felt matrix is high-performance because it holds shape under gravity and humidity swings. That’s due to the thermal bonded web. It can be vacuumed or wiped, and scuffs are often sanded lightly or replaced piece-by-piece. The polyester sound character is smooth and consistent between batches when you keep thickness and density aligned.

For specification packets, it helps to note delivery and labeling. As a panels manufacturer and project supplier, we prepare drawings and mounting details; still, the tone of this guide is practical: any trade can follow the steps to plan coverage, test, and tighten the result.

Rule-of-thumb coverages

Indicative absorption table (representative lab values)

| Build | 250 Hz | 500 Hz | 1 kHz | 2 kHz |

| 12 mm flush | 0.25 | 0.55 | 0.85 | 0.95 |

| 12 mm + 25 mm gap | 0.45 | 0.75 | 0.95 | 1.00 |

| 24 mm flush | 0.40 | 0.75 | 0.95 | 1.00 |

Use these as design hints; always check the selected product’s data.

For fundamentals of sound absorption, see the Acoustical Society of America’s plain-language note on absorption and how porous media absorb energy. For fire testing methods (ASTM E84) used to define class a fire performance, see a testing lab’s overview. Wikipedia’s primer helps contrast treatment and isolation.

Sources: Acoustical Society of America, Intertek on ASTM E84, Wikipedia: Sound absorption.

Are polyester panels only for speech?

No. They manage early reflections for both speech and music. Combine with bass control where low-end build-up is strong, and add diffusion for a natural field.

Can I get a decorative face without losing performance?

Yes. Keep the same thickness and the air gap behind the face. Patterned PET (slots/holes) still works if the open area and cavity are sized correctly—see decorative approaches similar to engraved / slotted PET concepts.

Will panels make the room “dead”?

Not if coverage is balanced. Start with first reflections, listen, then add. Most teams stop when dialog is clear and music remains lively.

What if I need isolation rather than treatment?

You need mass, seals, and joints for soundproof performance. PET treats reflections inside the room; it does not block sound through partitions.

How do I choose thickness?

12 mm for speech-first rooms; thicker or gapped builds when you need more low-mid control. See field references comparable to PET polyester acoustic panels.