Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86-13678899682 directly.

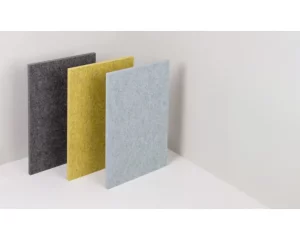

You want quieter rooms and a warm, soft finish. But you also worry about fire. If the walls are covered in fabric-like panels, will they feed a blaze or help control it? PET felt looks like cloth, so it raises real safety questions. Let’s clear them up.

On its own, polyester PET felt can burn, but modern acoustic PET felt panels are designed to be flame retardant rather than highly flammable. With the right density and additives, many products reach Class A or B fire ratings in tests such as ASTM E84, so they can meet fire safety requirements when correctly installed.

PET felt is a type of polyester felt made from fine fibers of polyethylene terephthalate, the same pet plastic used in drink bottles. In simple terms, this felt material is a soft but dense textile sheet created when the fibers are carded, layered, and heat-pressed together. Modern pet felt made for interior projects usually comes as rigid felt panel boards in standard sizes and thicknesses.

The base material is high-quality polyester fiber, and the raw material is carefully cleaned and prepared before production. In many factories, the sheets are made from recycled PET flakes or made of recycled fibers blended with virgin content to balance cost, color stability, and stiffness.

The felt is made without weaving or knitting; instead, pressure and heat bond each polyester fiber into a strong and durable mat. This gives PET felt its mix of softness, form stability, and impact resistance that designers like for wall and ceiling finishes.

As a professional manufacturer in China, we run this process in-house, which lets us control color, density, and thickness for different architectural and acoustic needs.

What is PET felt

Like any polymer, PET can catch fire if exposed to enough heat. But dense PET felt used on walls and ceilings is engineered to slow flame spread and improve fire resistance. The fibers melt and shrink away from the flame, and the panel structure tends to char rather than flash up like paper.

In other words, with the right recipe, the material becomes more fire resistant than many decorative fabrics or thin foams used in interiors. Additives and controlled density boost the flame retardancy of the panel, so it does not drip burning material and does not support a high fire growth rate the way some plastics do.

When PET felt is engineered and tested correctly, you can specify it as a fire-resistant finish within the limits of local code, while still keeping the good acoustic properties that make it attractive for noisy rooms. That balance of safety and comfort is exactly what most architects, interior designers, and contractors are looking for.

The key is chemistry and structure. During production, the resin is modified into flame-retardant polyester before it becomes fiber. In our own lines, we use carefully selected flame-retardant polyester fibers so the protective behavior is “inside” the fiber, not just sprayed on the surface.

Inside each panel, the dense tangle of fibers creates a complex path for heat and oxygen. This slows burning and keeps the surface more stable. A small amount of retardant additives helps the char layer form quickly, which protects the inner layers and reduces smoke release compared with untreated fabrics.

This combination lets PET felt reach demanding fire classes while still behaving like a soft, workable panel that can be cut, beveled, or CNC-milled into patterns without losing its safety performance.

What makes PET felt fire retardant?

Fire performance is not a guess; it is measured. Around the world, PET polyester fiber acoustic panels are tested to well-known international standards such as:

When acoustic panels are made for export markets, manufacturers like us typically test them to at least one of these systems. High-quality PET felt boards often achieve Class A or B under these methods, meaning they resist ignition, limit surface burning, and keep smoke at controlled levels.

To make life easier for specifiers, many of our products meet ASTM E84 class A, which is widely accepted in schools, offices, and other commercial interiors.

Here is a simplified comparison for typical 9–12 mm PET felt panels, based on common published data:

| Material type | Typical test | Typical class* | What it means in practice |

| PET polyester acoustic panels | ASTM E84 | Class A or B | Slow surface burning, suitable for most interior uses |

| Mineral fiber ceiling tile | ASTM E84 | Class A | Non-combustible core, common in ceilings |

| Thin decorative fabric on foam | ASTM E84 | Often B–C | Depends heavily on backing and treatment |

*Actual class depends on specific product and installation.

One of the big benefits of pet felt is how it helps with sound absorption and overall acoustic performance while still looking clean and modern. By tuning density and thickness, PET felt can reach high NRC (Noise Reduction Coefficient) values. Tests show that 12–25 mm polyester panels can offer excellent sound absorption, especially in the speech range, making meeting rooms, classrooms, and open offices more comfortable.

When you use sound-absorbing materials like PET in an acoustic treatment plan, you reduce echoes and lower ambient noise. The panels don’t block all noise like heavy concrete; instead, they act as sound-absorbing “sponges,” turning sound energy into a tiny amount of heat inside the fiber network. This also adds modest sound insulation between adjacent spaces when panels are combined with solid backing.

For designers, PET felt acoustic panels are flexible tools:

Because the panels are lightweight, panels are an excellent choice for renovation projects where you want to improve the acoustics of your space without heavy construction.

Most projects we support are public spaces like schools, libraries, offices, and transport hubs. In these environments, safety, durability, and ease of maintenance matter as much as acoustics.

Well-designed PET felt can handle daily wear and tear while staying stable on the wall or ceiling. The finished panel is a durable material that is dent-resistant, cleanable, and reasonably resistant to heat from sunlight or nearby light fixtures. Combined with proper fire tests, this gives specifiers confidence.

Because the wall panels are tested and certified, they help you meet fire safety codes in many regions when installed according to the manufacturer’s details. At the same time, a felt wall surface creates a warm, quiet feel that people enjoy far more than bare concrete or metal. For busy corridors or open-plan offices, these panels are easy to integrate with lighting, signage, and other interior elements.

PET felt for offices

Compared with traditional felt made from wool or mixed fibers, PET felt is more consistent, more dimensionally stable, and easier to fabricate at large sizes. Wool can char nicely in a fire, but it is harder to standardize and more sensitive to humidity and moth damage.

If you compare PET felt to other acoustic panels on the market, you will see that polyester acoustic panels often sit between soft fabrics and rigid mineral boards. They offer better design freedom than typical fiberglass tiles while avoiding the brittle feel of some hard boards. For feature acoustic felt panels, baffles, and ceiling rafts, this balance of stiffness and softness is very useful.

From a product family view, pet panels come in many materials available such as plain sheets, slatted profiles, 3D tiles, and printed surfaces. For distributors and brand owners, this is a chance to build a rich product line using one core technology.

A big advantage of PET felt is sustainability. Most boards use a high percentage of recycled plastic. In many cases, they use PET flakes from plastic bottles that have been sorted and cleaned. These are melted and spun into fibers, then turned into panels. Some products are even made from recycled plastic bottles at rates of 60–75%.

This process supports the recycle economy by turning made from recycled plastic bottles waste into long-life building components. It is both eco-friendly and environmentally responsible, especially when panels can be recycled again at end of life.

For architects and brand owners working on green buildings, PET felt is often promoted as made of recycled content. When combined with low-VOC binders and clean production, this can help contribute to sustainability certifications and client targets.

As a specialist factory in China, we focus on pet felt products and wood acoustic panels for global B2B clients. Our PET lines produce a wide range of pet acoustic panels and pet felt panels in different colors, densities, and thicknesses to match real-world project needs.

Because we handle compounding, fiber production, and panel pressing ourselves, we can tune the mix of safety and performance. We design our boards as acoustic panel solutions that balance fire behavior with comfort and design:

For distributors, importers, and OEM/ODM brands, this means you can build your own label on top of our technical base. For contractors and design firms, it means you get tested, documented panels you can specify with confidence.

To make the picture clearer, here is a compact view of typical PET felt performance (values are representative of good products on the market):

| Property | Typical PET felt board (12 mm) |

| Composition | 100% polyester (PET) with flame-retardant polyester fibers |

| Fire test | ASTM E84 / EN 13501 / GB 8624 |

| Typical result | Class A or B, controlled flame spread |

| Acoustic NRC | 0.45–0.75 depending on mounting (good acoustic performance) |

| Use cases | Offices, classrooms, theaters, transport halls |

Always check the specific test reports for the exact product you plan to use.

Yes—when you choose tested panels from a reputable manufacturer, PET felt can be used in many code-regulated interiors. In China, high-quality polyester boards typically reach B1 flame-retardant levels under GB 8624, meaning they are not easily ignited and self-extinguish after flame removal, satisfying the fire safety requirements of most indoor projects.

PET felt is one of several sound-absorbing materials used for acoustic treatment. Compared with mineral wool, it is cleaner to handle and easier to shape. Compared with thin foam, it is more robust and long-lasting. For many designers, PET-based acoustic felt strikes a good balance between performance, cost, and design freedom.

Yes. When you add enough coverage, especially on hard parallel walls, PET felt helps control echoes and ambient noise. Panels installed at key reflection points change the acoustic properties of the room, making speech clearer and reducing fatigue. For many offices and classrooms, this single step makes the room feel calmer and more focused.

Most acoustic felt panels are designed so that installers can cut them on site and glue or mechanically fix them to substrates. This makes the system fast to fit, even on curved surfaces or complex shapes. For contractors, this is one reason these wall panels and ceilings are popular: they save labor without sacrificing safety.

PET felt boards add a small amount of insulation and sound insulation, because trapped air in the panel slows both heat flow and sound. They do not replace dedicated insulation in the building envelope, but they can boost comfort when combined with other layers in a wall or ceiling build-up.

If you are a distributor, importer, architect, or contractor planning a large project, the best path is to work directly with a factory like ours. We can advise on pet felt products, thickness, density, fire tests, and finishing so the system fits your project brief and local code. From our experience supplying PET-based acoustic panel solutions worldwide, we know that early technical input helps projects run smoother and safer.

To sum up: PET felt is not a magic, non-burning material, but when engineered correctly it behaves as a controlled, fire-resistant acoustic finish that fits modern interiors very well. It offers reliable sound control, a soft visual feel, and a convincing sustainability story built on recycled plastic bottles and recycle-friendly production.

As a professional manufacturer in China specializing in PET and wood acoustic systems, we help B2B clients turn these technical facts into real business value—quiet, safe, beautiful spaces that meet design goals and code at the same time.

If you are planning your next office, school, hotel, or transport hall and need tested PET pet felt acoustic panels or other pet acoustic panels, we can support you with data sheets, samples, and OEM/ODM branding options. Reach out to our engineering team, and let’s design fire-safe, comfortable acoustical interiors together.