Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86-13678899682 directly.

If your room sounds sharp, “boomy,” or tiring, it’s easy to buy the wrong thing fast. Then you hang it up… and nothing feels better. That wasted budget hurts. The good news: once you understand what shape really changes (and what it doesn’t), you can pick the right treatment the first time.

Yes, the shape of an acoustic panel or acoustic foam can matter—but mostly for how sound reflects and which frequencies get tamed, not for “blocking noise.” Flat panels, wedges, and other profiles mainly change surface area and scattering. Thickness, material, mounting, and coverage usually have a bigger impact than the foam shape alone.

When people say a room sounds “loud,” they often mean the reflections are too strong. A sound wave leaves the speaker, hits a hard surface, and bounces back. Those repeated bounces build up messy echoes and blur speech.

Here’s the simple idea: an acoustic panel works by letting air move through a porous surface (like PET felt or mineral fiber) and turning part of that motion into tiny amounts of heat. That reduces reflections and improves speech and music clarity. In other words, the panel absorbs some of the sound energy, so you hear less slapback and less harshness.

In our projects, we explain it like this: you’re not “removing sound,” you’re managing room sound. The goal is cleaner sound quality, better comfort, and more predictable sound control—especially in meeting rooms, open offices, studios, and public spaces.

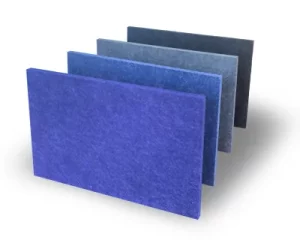

acoustic panel

Many buyers search “soundproof foam” and expect it to stop noise from neighbors. But soundproof and absorption are different jobs.

A quick rule we share with architects: soundproofing blocks sound from entering a space by adding mass, sealing gaps, and breaking vibration paths. If you want to reduce sound from passing through walls, you usually need heavy layers (drywall, concrete, mass-loaded barriers), airtight sealing, and decoupling—not just foam on the walls.

That’s why “soundproof foam” is a confusing phrase in the market. Foam may reduce ringing and flutter echo, but it rarely stops neighbor noise on its own. If your main pain is echo, go for absorption. If your pain is leakage, design for isolation (and then add absorption for comfort).

Practical note: a strong acoustic treatment plan often combines both—construction details for isolation and sound absorbing finishes for comfort.

Let’s talk about foam. Most acoustic foam is porous and works best on mid and high frequencies. Designers shape it into wedges, pyramids, and ridges for a reason: the profile increases surface area and helps scatter reflections so you hear less “zing.”

This is the core of foam shapes and their uses:

But here’s the honest truth we tell B2B buyers: acoustic foam shapes can improve perceived echo control, yet thickness, density, and placement usually matter more than the pattern. A thin, pretty pyramid tile can look professional while still doing little at lower frequencies.

If you need a simple mental model, focus on where the reflections hit first (front wall, side walls, ceiling cloud), then pick the right material and thickness. Foam panels are often used as fast, lightweight fixes in smaller rooms. For large commercial spaces, many clients prefer PET felt wall panels or slatted wood panels because they combine design with predictable performance.

This is the heart of your question: does the shape of acoustic products change performance?

Sometimes, yes—but within limits.

What shape helps with

What shape usually does not fix

When we compare samples in our own internal checks, we treat shape as a “fine-tuning knob.” If you want to absorb more sound, start with thickness and coverage first, then choose a profile if you want extra scattering on the surface.

| Option | Typical best use | What it’s weak at | Notes for spec writers |

| Flat PET felt acoustic panel | Speech clarity, open offices, classrooms | Deep bass without air gap | Easy to cut, stable, good OEM branding |

| Wedge/pyramid acoustic foam | Small room echo control | Isolation and low-frequency control | Light, fast install, style-driven |

| Slat wood acoustic panel (with backing) | Design + absorption | Needs correct backing for results | Great for lobbies, retail, feature walls |

| Thick mineral/fiberglass absorber | Broad-band absorption | Needs fabric finish for aesthetics | Common in studios and auditoriums |

NRC and absorption data are typically measured in reverberation rooms using standards like ASTM C423 and ISO 354, which helps you compare products more fairly.

If you remember one thing, remember this: sound absorption is strongly tied to thickness and mounting, not just the pattern on the face.

Here’s why: lower-frequency waves are longer. A thin tile can’t interact deeply with that wave, so it mostly affects higher bands. Thicker products give the wave more “path length” inside the porous structure, so more energy gets converted.

Absorption tends to improve as thickness increases, especially at lower frequencies:

Also, an air gap behind a panel can boost low-frequency effectiveness because the wave “sees” more depth. This is one reason professional soundproofing panels and absorbers are often mounted with space behind them, not glued flat.

In our production runs, we often explain: panels are designed to manage reflections. But the “depth” of the absorber (material thickness + air gap) is what makes the biggest difference when clients complain about rumble or bass.

Many buyers ask for acoustic panels vs foam as if one is “good” and one is “bad.” Reality is more practical: it depends on the room, the goals, and the finish.

acoustic panels vs foam often comes down to:

A big difference is how products are built. Many panels are rigid or semi-rigid and can be engineered for consistent density and thickness. Acoustic foam panels can be effective in small rooms, but they’re not always the best choice for large commercial projects that require clean edges, stable color, and standard compliance.

A helpful way to say it: panels offer more design integration and predictable mounting options; panels don’t solve isolation by themselves. (And neither does foam.) If your goal is a polished architectural look, PET felt and slatted wood acoustic wall panels usually fit better than studio-style tiles.

For buyers comparing absorption ratings, NRC is commonly used as a single-number summary of mid-frequency absorption (often averaged across 250, 500, 1000, and 2000 Hz).

foam vs. PET felt vs. wood slats

There are many different types of acoustic panels, and each one has a “sweet spot.”

In our factory, we see how spec needs change by project: some clients want decorative panels for branding; others want standard acoustic modules for fast installation; some need an acoustic ceiling cloud system to reduce reverb without touching the walls.

One key manufacturing note: panels made from PET felt or composite structures can be cut, grooved, and shaped with consistent tolerances—helpful for OEM/ODM work. This is why brand owners and distributors often ask us for custom panels with private labels, custom colors, and repeatable dimensions.

We respect diy acoustic panels—they can be a great learning step. But in B2B projects, DIY can become expensive when it fails inspection, looks uneven, or performs inconsistently.

Common DIY risks:

For project work, custom acoustic panels usually win because they can be engineered and documented. We often build a package that includes drawings, batch consistency, and optional branding—especially for contractors who need predictable installation and fast site acceptance.

Here’s a simple checklist we share with purchasing teams:

Let’s make this concrete. The “right” solution changes by space because the type of sound and reflection pattern changes.

Goal: reduce chatter fatigue and improve speech clarity. PET felt sound absorbing panels on walls plus ceiling clouds works well. Add partitions if needed. In many office layouts, installing acoustic clouds above collaboration areas is the fastest win because ceilings are often the largest reflective surface.

PET felt sound absorbing panels on walls plus ceiling clouds

Goal: speech intelligibility. Teachers need less reverb so students understand words. Use PET or fabric systems; add ceiling treatment. Keep the layout simple: cover first reflection points and large flat surfaces.

Goal: reduce overall loudness so people can talk. Here, acoustic baffles and ceiling features often look best and work well. Clients typically want treatment that blends with interior design, so slat wood or PET décor works.

Goal: cleaner dialogue and controlled reflections. Treat side walls and the front wall, add a ceiling cloud, and consider corner bass control. In a home theater, you’re aiming for the best sound, not just “less echo.”

If you want a quick win, put acoustic where reflections hit first, then add coverage until the room feels calm. Don’t overthink the pattern on the surface before you solve coverage and thickness.

If you’re buying for projects, don’t guess—spec.

NRC is helpful, but it’s not everything. NRC is a simplified average. It’s measured using lab methods like ASTM C423, and absorption can vary by mounting, air gap, and sample size.

ISO 354 is another widely used approach for measuring absorption in a reverberation room.

A short standard description you’ll often see is that ISO 354 specifies a method for measuring the sound absorption coefficient “in a reverberation room.”

Many buyers obsess about shapes, but coverage is king. Panels come in many styles; choose what you can actually install at scale and keep clean.

If you want, send us your room dimensions, ceiling height, photos, and usage. We’ll recommend a layout that balances cost, design, and performance—so you get the right acoustic panel the first time.

Problem: strong echo and poor speech clarity during safety training.

Solution: PET felt wall coverage at first-reflection points + ceiling cloud; minimal design change.

Result: a noticeably calmer room sound, clearer speech, and less fatigue for attendees (especially in long sessions).

Problem: customers complained it felt “too loud,” even when music was low.

Solution: ceiling baffles + decorative PET panels on large flat wall areas.

Result: lower perceived loudness and better conversation comfort, without changing the interior style.

(Exact performance depends on room volume, surfaces, and coverage. We can model options and confirm targets with test-backed products.)

A little. It can help scatter reflections and reduce flutter, but thickness, density, and coverage usually matter more than the surface pattern.

For most acoustic use, yes—open cell foam lets air move through pores, which helps convert sound energy into heat and reduce reflections.

Usually no. Foam helps with echo. If your main goal is stopping noise leakage, you need mass, sealing, and construction changes.

Many projects choose PET felt panels or wood slat systems with absorber backing. They’re clean, stable, and easy to match to interior design.

Ask for absorption test info and standards (ASTM C423 or ISO 354), and make sure the mounting method in the data matches your planned installation.

No. They help a lot, but layout, coverage, and sometimes isolation details matter too. Think of them as part of a complete plan for better sound within a space.