Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +86-13678899682 directly.

Are you battling noise and hoping acoustic fixes will finally bring peace? You’re not alone. Noise leaks, echo, and distraction hurt work and wellbeing. Let’s clear up what acoustic panel products do—and what soundproof systems do—so you can choose the right solution.

Acoustic panels don’t block sound both ways. They absorb sound to reduce echo and improve sound quality, but they do not stop sound transmission through walls. For true soundproofing, you need added mass, airtightness, and decoupling, not just panels.

We manufacture PET and wood acoustic panels in China for global B2B projects. Below, we explain how acoustic and soundproof systems differ, when each is useful, and how to combine them for real-world results. You’ll also find practical tables, simple rules of thumb, and field-proven guidance from large commercial and public projects we supply worldwide.

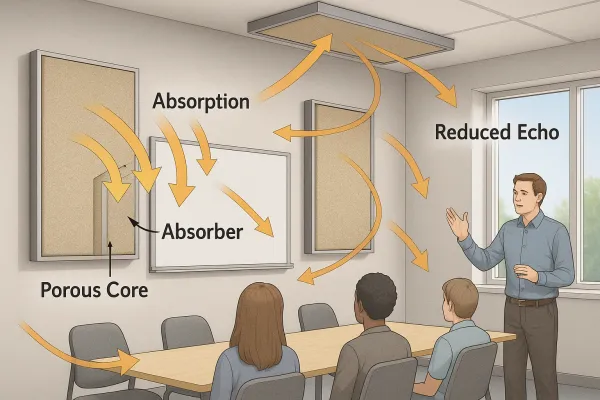

Acoustic panels are decorative wall panels or ceiling elements that absorb sound. When sound hits them, sound energy is converted—mostly sound energy into heat—reducing the amount that would otherwise bounce around the room. This function is to absorb sound, not block it like masonry or laminated partitions.

What is an acoustic panel and how does it work?

Typical acoustic panels are made from dense polyester (PET), mineral fiber, timber slats on backing felt, or acoustic foam. Because these panels are designed with porous cores and micro-air paths, sound is absorbed as pressure waves enter the material. In simple terms, acoustic panels are designed to reduce reflections and reverberation so speech is clearer and meetings run smoother.

In practice, panels are designed to absorb mid to high frequencies (speech range) very efficiently. At low frequencies (HVAC rumble or bass), you need special deep absorbers or tuned traps. Still, panels reduce flutter echo and harshness fast, which panels can make offices, classrooms, and lobbies feel calmer.

As a factory supplier, we tailor thickness, density, and perforation so acoustic performance matches your room goals.

Explore material options: PET Acoustic Panels and Wood Acoustic Panels.

Many teams wonder if panels work both ways—that is, do they stop noise in both directions? In a word: no. You’ll often see the myth that soundproof panels work both ways, but acoustic panels don’t block. They panels primarily absorb reflections inside a room, lowering the overall amount of noise that escapes. But they do not block noise transmission through a wall.

Think of it this way: acoustic treatment controls reflections within a room and inside the room; soundproofing slows sound transmission through barriers. Because absorption lowers the in-room sound level, panels can reduce how much escapes, but they are not designed to block structure-borne or airborne transfer.

For deeper detail on project integration, see our acoustic treatment ideas and slat options in PET Slat Panels.

Soundproof assemblies (walls, doors, floors) are designed to block transfer by combining mass (e.g., drywall layers), damping, airtight seals, and often materials like resilient channels for decoupling. They block sound transmission and block sound from entering adjacent rooms. They are your true soundproofing backbone.

By contrast, acoustic products improve sound quality by reducing reflections. They tame echo, they do noise reduction in the talk zone, and they improve the sound of speech and music, but they don’t block external noise by themselves. Soundproofing requires construction-layer changes; soundproofing panels depends on mass, seal quality, and continuity.

Use both together for optimal soundproofing:

See our designer-friendly options for front-of-house spaces: Perforated PET Decorative Panels.

Acoustic foam is lightweight, easy to mount, and great at taming mid/high reflections. But foam panels don’t block. They’re absorbers. The phrase foam work both ways pops up online, yet acoustic foam works by absorbing—not by stopping transfer through partitions. The same reality applies if you ask whether foam work both ways in halls or offices.

In some installs, foam may slightly reduce what neighbors hear because it lowers in-room level. But again, that’s not the same as a barrier. If you need better soundproofing, adjust the wall build, not just the finish layer. For architectural aesthetics, consider wood-on-PET slats: Wood Acoustic Panels.

Absorbers absorb sound waves as they pass through a porous core. That absorption trims reflections, helps reduce echo, and panels improve speech clarity. With fewer reflections, you reduce noise levels from chatter. Effective use will improve sound quality in meeting rooms, schools, and venues.

The basics of sound absorption

Key points on sound absorption:

A typical PET panel (12 mm) vs slat panel (wood veneer over PET felt):

| Product type | Typical thickness | NRC (broadband) | Primary benefit |

|---|---|---|---|

| PET flat panel | 9–12 mm | 0.70–0.85 | reduce echo for speech |

| Wood slat on PET | 20–25 mm | 0.75–0.95 | Adds design + absorption |

For signature walls that are both decorative and functional, see Engraved V-Slot PET Panels.

Effective projects place acoustic wall panels at first-reflection points on wall or ceiling, behind talkers, and opposite large glass surfaces. When panels are installed at these locations, they catch early reflections and room by reducing echo you get calmer conversations.

Quick placement rules:

Installation tip: install acoustic panels with a slight air gap (25–50 mm) for deeper absorption efficiency.

To align with interior palettes, acoustic panels come in felts, veneers, and custom colors. Need a consistent brand look? Talk to us about OEM finishes on PET Acoustic Panels.

To block unwanted noise, add mass (double gypsum), damping membranes, and airtight seals around outlets and doors. To absorb reflections, use acoustic finishes like PET felt and slatted wood. For cost control, combine both: build a good barrier, then finish with absorbers.

Glossary at a glance:

About “foam barriers”: Despite marketing phrases like soundproofing foam work, foam isn’t a wall. It’s a finish. Plan barriers first, then select acoustic panels and acoustic foam to fine-tune the space.

PET felt

A 1,200 m² open office had external noise from a café and a corridor. We supplied PET and wood-slat acoustic finishes. Adding 35% wall coverage near collaborative zones plus ceiling baffles cut RT60 by ~40%. That lowered noise levels and raised speech privacy perceived by staff.

Important note: acoustic panels may reduce what neighbors hear because the in-room level drops, but they do not block external noise on their own. For adjacent room privacy, upgrade the partition and add seals. Then use acoustic finishes to tune the space. See finish options in Technical Wood Veneer Panels.

Absorbers reduce reflections and chatter; they don’t stop sound from entering or leaving. To prevent noise from entering or leaving a room, build better partitions. That means sealed doors, continuous mass, resilient channels, and damped layers. After that, add acoustic finishes to polish speech clarity.

Think in layers:

If your goal is to block sound from entering a meeting room, treat the wall assembly—not just the finish. For finishes that keep the brand look while tuning acoustics, explore Perforated PET Decorative Panels.

Set expectations clearly with stakeholders. Absorbers deliver fast comfort wins and sound control for speech; barriers deliver privacy. Combining both brings best soundproofing solutions at scale.

Project checklist:

Remember: acoustic panels cannot fix a leaky door frame, and acoustic panels don’t seal electrical boxes. Soundproofing requires construction upgrades; finishes then refine the experience. Need help scoping soundproofing solutions from schematic to install? Our engineering team can assist.

| Goal | Solution Type | What it does | Notes |

|---|---|---|---|

| Speech clarity | Acoustic PET/wood panels | Absorb reflections; absorbing excess sound | Choose thickness and coverage by room size |

| Privacy between rooms | Mass + damping + seals | Block noise transfer | Specify STC targets; seal doors & penetrations |

| Echo control in glass atriums | Ceilings + walls | panels can reduce reverberation | Combine baffles + wall coverage |

| Low-frequency control | Deep absorbers | Target bass build-up | Corner traps or thick cavities |

If you can still see daylight around a door, you don’t have a sound barrier. Fix the leaks first, then finish the space. That’s how you get better soundproofing and a pleasant, usable room.

Do acoustic panels block sound both ways?

No. Absorbers tame reflections in the treated space; barriers handle privacy. If you need sound stopped entering or leaving a room, upgrade the wall/door assembly first, then finish with absorbers.

Can acoustic panels stop music from a next-door studio?

They might lower in-room loudness, but they won’t stop external noise from entering by themselves. Meeting your goal depends on the wall’s STC and sealing.

Will acoustic foam soundproof my apartment?

Foam reduces echo; it doesn’t seal gaps or add mass. Use a real barrier to slow transfer, then absorbers to tidy reflections.

Where should I start on a tight budget?

Seal doors and penetrations (barrier), then add targeted absorbers at first reflections. This brings big returns with modest cost.

What makes a good soundproof wall?

Mass (two layers of drywall), damping (viscoelastic compound), decoupling (resilient channels), and airtightness throughout.

Do you customize panels for brand projects?

Yes—OEM/ODM colorways, sizes, slat spacing, fire ratings, and CNC patterns to match design intent, schedules, and logistics.